CNC Design retrofitting a large roll grinder

CNC Design retrofitting a large roll grinder

Customer: New Zealand Steel

End User: New Zealand Steel

Industry: Machine Tools

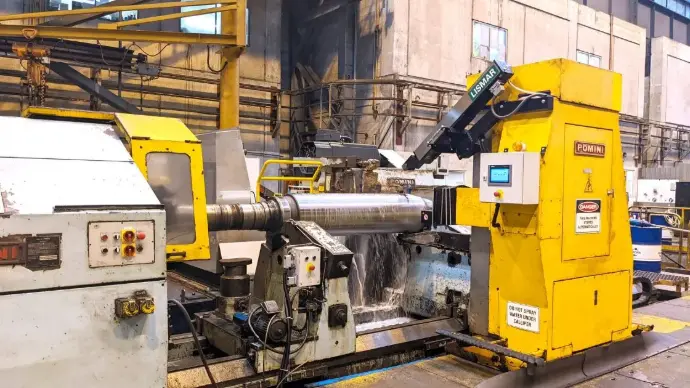

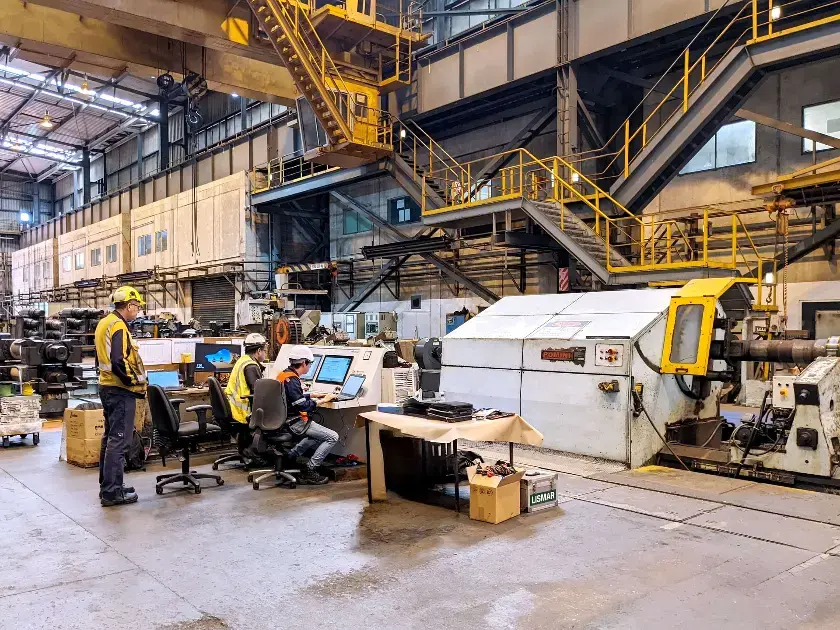

Project: CNC Retrofit of Pomini 400-425 Roll Grinder

The end user

New Zealand Steel (part of the BlueScope group), situated in Glenbrook, South Auckland, is the country's leading producer of flat-rolled steel products. With a focus on quality and innovation, the company manufactures a diverse range of steel products essential for construction, manufacturing, and infrastructure projects nationwide. Using state-of-the-art technology and environmentally sustainable practices, New Zealand Steel delivers high-quality hot-rolled and cold-rolled coil, metallic-coated steel, and steel billets to meet the diverse needs of its customers. Committed to both excellence and sustainability, New Zealand Steel plays a pivotal role in supporting the nation's growth and development while prioritizing environmental stewardship and community engagement.

The Equipment

The Pomini 400-425 Roll Grinder is a heavy-duty machine renowned for its precision grinding capabilities, commonly found in rolling mills worldwide. With advanced features like high precision grinding and precise control over the process, it ensures efficient material removal while maintaining superior surface finish and dimensional accuracy. A comprehensive electrical retrofit was done by CNC Design to enhance its performance further, along with additional equipment and services.

This included:

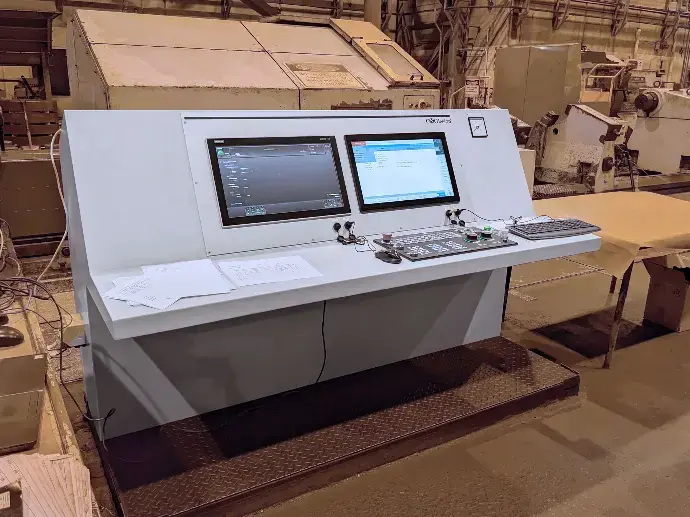

SINUMERIK ONE CNC system including SINUMERIK Safety Integrated

CNC Design ROLLGrind software for grinding, measuring and database for roll data management

New SINAMICS S120 drive system for all servo motors and spindle motors

New SIMOTICS 1FT7 servomotors for all axes

New SIMOTICS 1PH8 spindle motors grinding wheel and headstock drive

New roll defect scanning system based on Eddy currents and ultrasound scanning technologies

New main electrical cabinets with all new electrical switchgear

Why CNC Design?

CNC Design is an Australian company established in 1984 with core competencies in Machine Tools, Production Machinery and associated Motion Control products. With more than 140 people located in our offices in Australia, New Zealand and SE Asia, we have been the exclusive Siemens Solution Partner in this region for Machine Tool products and services for more than 30 years. CNC Design has experience working with our customers to develop customised solutions tailored to their applications with more than 2,000 projects completed in over thirty countries.

One focus for CNC Design has been roll grinding technology for the steel industry. Our customer base goes beyond our immediate region and includes East Asia & North America.

CNC Design is an Australian company established in 1984 with core competencies in Machine Tools, Production Machinery and associated Motion Control products. With more than 140 people located in our offices in Australia, New Zealand and SE Asia, we have been the exclusive Siemens Solution Partner in this region for Machine Tool products and services for more than 30 years. CNC Design has experience working with our customers to develop customised solutions tailored to their applications with more than 2,000 projects completed in over thirty countries.

One focus for CNC Design has been roll grinding technology for the steel industry. Our customer base goes beyond our immediate region and includes East Asia & North America.

We offer upgrading solutions for a wide range of roll grinders, including Pomini, Waldrich, Herkules & Toshiba Shibaura. Projects can be completed on site or in some cases we overhaul and retrofit machines for customers in our Thailand Factory, which is one of the world’s largest machine tool reconditioning facilities. We have well proven upgrade solution for Pomini Roll Grinders installed at several sites and can provide many references.

We offer upgrading solutions for a wide range of roll grinders, including Pomini, Waldrich, Herkules & Toshiba Shibaura. Projects can be completed on site or in some cases we overhaul and retrofit machines for customers in our Thailand Factory, which is one of the world’s largest machine tool reconditioning facilities. We have well proven upgrade solution for Pomini Roll Grinders installed at several sites and can provide many references.