CITIC Heavy Industries MAAG SH1200 Electrical & Mechanical Upgrade

CITIC Heavy Industries Project

The Customer

CITIC Heavy Industries Co. Ltd. (CITIC HIC) is a leading manufacturer of heavy-duty equipment with over 60 years of innovation and development. As a nationally and internationally recognized high-tech enterprise, it operates one of the largest manufacturing facilities globally and supports projects both in China and overseas. CITIC HIC maintains advanced R&D capabilities, including a special robot industrialization base, and holds multiple national technology and innovation certifications. With a strong global presence through overseas offices and service bases, the company implements international standards to ensure high quality and reliability. Committed to sustainable growth and continuous improvement, CITIC HIC aims to be the preferred global equipment manufacturer known for quality, innovation, and operational excellence.

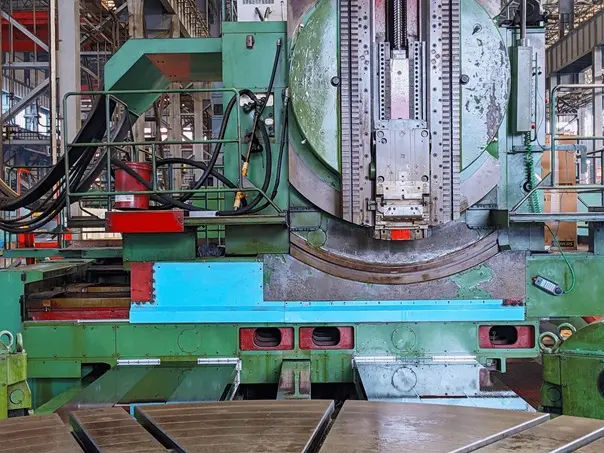

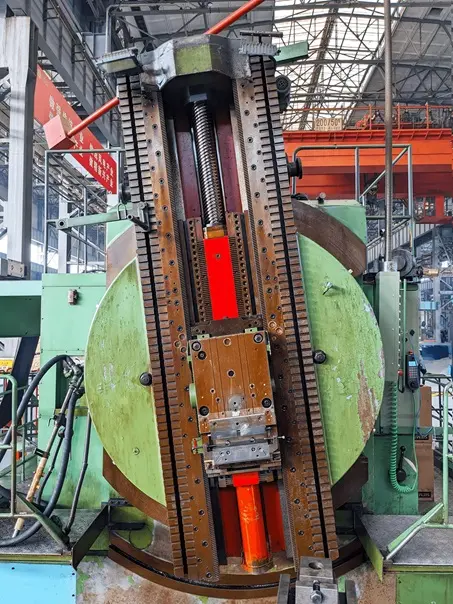

The MAAG SH1200 located at CITIC is used for cutting gears up to 12m diameter.

MAAG Gear cutting CNC operating software

CNC Design’s MAAGCut CNC operating software has been developed and proven on a large number of MAAG machines worldwide. It offers many significant improvements in machine set up and cutting, compared with the existing system. Utilising a CNC allows us to eliminate both the old electrical control system and also most of the interlinking gears and shafts. This greatly simplifies the machine and eliminates most of the difficult to get service items, ensuring your MAAG will be supported for many more years to come.

There is no need for detailed programming the CNC control for the MAAG machine as everything is parametrised by the operator based on gear geometry.

Conversion to CNC makes it easier to train new operators.

SINUMERIK ONE CNC System

The MAAGCut solution uses the latest Siemens CNC, SINUMERIK ONE, the flagship control in the Siemens CNC portfolio. SINAMICS S120 digital drives with SIMOTICS servo, spindle & torque motors are used for all axes including the cutting head. The SINUMERIK ONE includes an integrated S7-1500F Safety PLC which can control all machine auxiliary functions.

Operator Panel & Electrical Cabinets

MAAGCut Features & Benefits

While not making any changes on the basic principle of gear generating as designed by the machine manufacturer, this retrofit will significantly reduce the complexity of the current machine set up and machine usability.

- The cutting strategies and cutting programs are predefined in various cycles, which we have developed with the input of industry leaders using MAAG gear shapers. The actual CNC programming code is not required to be modified by the operator and is part of CNC Design Pty Ltd Intellectual Property.

- Operation of this machine is simple. All process data are entered into setup or operation screens, it can then be recalled from memory, or entered new, when the same job is repeated.

- Machining data can also be modified dynamically during machine operation. All information will be checked for correctness and a comprehensive operator guide and logical checks accompany these inputs

- New features designed for simplifying the operator’s tasks for setup, cutting monitor and measuring are provided.

CLIENT FEEDBACK

It is gratifying that the stability and accuracy of the machine are very good, and our company has given high praise to this project.

DOWNLOAD CNC Design Upgrades MAAG SH1200 for Citic Heavy Industries case study.