VSF Composite Printing

The VSF large-scale 3D printing solution offers a fully digital production process designed to enhance productivity and shorten production time.

Ideal for applications such as jigs, plugs & moulds, and structural or decorative end-parts, this solution serves multiple industries.

Utilising a wide range of reinforced thermoplastic materials, it is engineered to meet diverse application requirements.

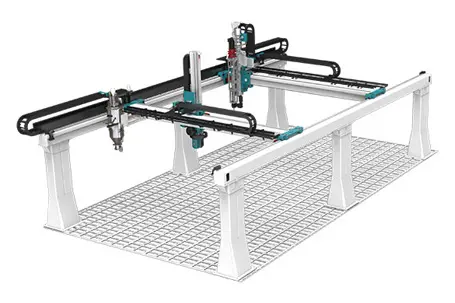

VSF 3D Printing Solution

Hybrid System

The VSF system combines Large Scale 3D printing with 5-axis high speed milling in a single integrated Manufacturing Centre.

Pellet Extrusion

VSF uses extrusion based Additive Manufacturing with a large print bead width from 5 mm to 50mm. Fiber-reinforced thermoplastic polymer pellets are melted and extruded in precise-layers to form a unified structure.

5-Axis Machining

3D printed parts are machined to precision tolerances and high surface finish, the printed near net shape component. VSF is a high performance 5-axis milling system.

Key Advantages

Versatility

Tailor the VSF System to match your specific needs. Whether you require a 6x6m printer or a 22m dual bridge hybrid system, we provide configurations to suit your application perfectly.

Flexibility

With the ability to print vertically and at 45°, and compatibility with a variety of materials, including PA, PP, PESU, PEI, PET, ABS, and beyond, the VSF system offers unparalleled flexibility in operation.

Quick ROI

Thanks to its high print speeds, ultra-energy-efficient material dryer, and low maintenance costs, the VSF System assures a swift return on investment.

Its speed, efficiency, and cost-effectiveness make it a valuable asset in your operation.

Sign Up to Get the VSF large-scale 3D printing brochure