#11-2 Design and build of the 3D Printing Gantry with a single bridge and a vertical beam with the advanced print nozzle

Customer: One COMPOSITES

Segment: Large scale 3D printers

Project: VSF Gantry Printing and

Milling and Robotic Spraying

#11-2 Design and build of the 3D Printing Gantry with a single bridge and a vertical beam with the advanced print nozzle

Customer: One COMPOSITES

Segment: Large scale 3D printers

Project: VSF Gantry Printing and

Milling and Robotic Spraying

The Customer

Queensland manufacturer One Composites, a

fully owned subsidiary of Zone RV, where their

VSF-3D printing system is the largest in the

Southern Hemisphere. The 22m x 5m x 1.6m

system was initially established for both 3D

printing and machining in composite materials for

a wide range of off-road caravans that combine

lightweight composite bodies with lass-leading

components.

Why CNC Design?

CNC Design, an established Australian company

with core competencies in Machine Tools,

Engineered Drives, Robotics, and Additive

technologies, has recently commissioned a new

range of large-scale additive VSF-3D printers.

These thermoplastic composite printers have the

potential to revolutionise the manufacturing

industry by enabling the production of a wide

range of items such as plugs, moulds, fixtures,

structural components, formwork, decorative

pieces, and architectural parts.

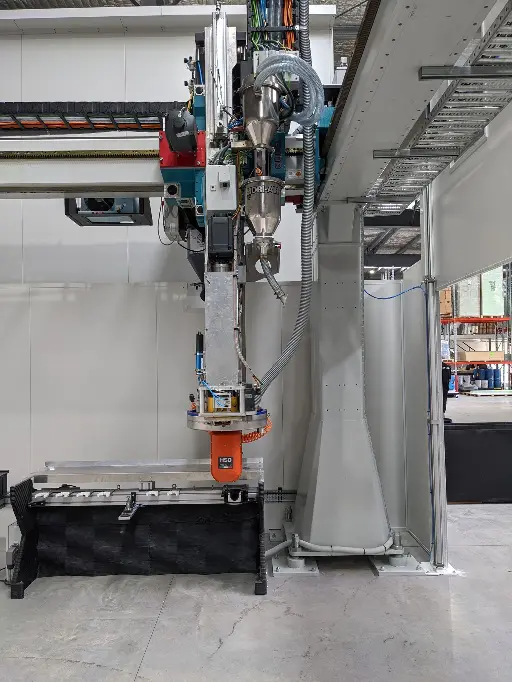

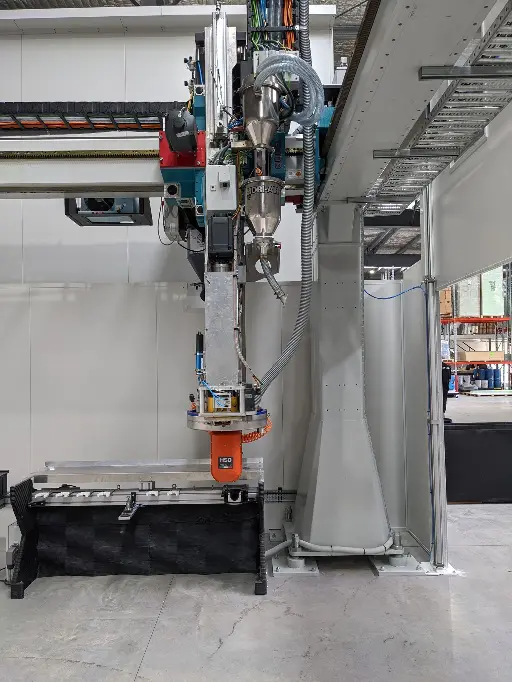

The Equipment

At One Composites CNC Design's Virtual Smart Factory (VSF) platform stands at the forefront of Industry 4.0, representing a digital robotic system that harnesses the power of standard modular and versatile components. Tailored for additive, machining, and handling applications, VSF is a robust solution that redefines manufacturing processes.

At its core, VSF is propelled by the SIEMENS

SINUMERIK ONE CNC system, offering distinct

advantages over conventional Robot controllers

with its exceptional path accuracy and a

user-friendly standard CNC G Code programming

interface. Adding to its capabilities, the integration

of the HSD HS673 2-axis milling head, affixed to

the Z-axis vertical beam, ensures precision and

efficiency in high-speed 5-axis milling operations

for composites, wood, and plastics.

Why CNC Design?

CNC Design, an established Australian company

with core competencies in Machine Tools,

Engineered Drives, Robotics, and Additive

technologies, has recently commissioned a new

range of large-scale additive VSF-3D printers.

These thermoplastic composite printers have the

potential to revolutionise the manufacturing

industry by enabling the production of a wide

range of items such as plugs, moulds, fixtures,

structural components, formwork, decorative

pieces, and architectural parts.

The Equipment

At One Composites CNC Design's Virtual Smart Factory (VSF) platform stands at the forefront of Industry 4.0, representing a digital robotic system that harnesses the power of standard modular and versatile components. Tailored for additive, machining, and handling applications, VSF is a robust solution that redefines manufacturing processes.

At its core, VSF is propelled by the SIEMENS

SINUMERIK ONE CNC system, offering distinct

advantages over conventional Robot controllers

with its exceptional path accuracy and a

user-friendly standard CNC G Code programming

interface. Adding to its capabilities, the integration

of the HSD HS673 2-axis milling head, affixed to

the Z-axis vertical beam, ensures precision and

efficiency in high-speed 5-axis milling operations

for composites, wood, and plastics.

Application Centre

This new facility is supporting One Composites

and other clients in the development and testing

of INNOMERIX's new advanced materials that

are specifically formulated for large scale printing

and machining. The application centre includes

highly specified VSF-3D printer, with a print area

of 12m x 5m x 1.6m, integrated on the same site

as INNOMERIX. Having in-house testing

laboratory, ensures that material properties and

performance can be tested, logged and retained

for customer's and future reference. The centre

also supports VSF-3D sales demonstrations, and

production of specialty components on a

commercial basis.

Design Overview

The VSF-3D printer uses a large area gantry to

carry a patented multi zone extruder for melting

and extrusion, providing the ability to rapidly print

large structures with reinforced composites up to

150kg/hr. In addition, the printers offer an optional

5-axis machining head can provide smooth

surface finishes.

The printers have several other features,

including a nozzle rotation unit with a

temperature-controlled roller to flatten and

compress print bead, a vacuum pellet drying and

conveying system with high performance and

energy efficiency for continuous printing, axis print

speeds up to 20 m/min with axis rapid speeds up

to 60 m/min, changeable nozzles, and Siemens

SINUMERIK ONE controls, the leading platform

for advanced manufacturing.

Application Centre

This new facility is supporting One Composites and other clients in the development and testing of INNOMERIX's new advanced materials that are specifically formulated for large scale printing and machining. The application centre includes highly specified VSF-3D printer, with a print area of 12m x 5m x 1.6m, integrated on the same site as INNOMERIX. Having in-house testing laboratory, ensures that material properties and performance can be tested, logged and retained for customer's and future reference. The centre also supports VSF-3D sales demonstrations, and production of specialty components on a commercial basis.

Design Overview

The VSF-3D printer uses a large area gantry to

carry a patented multi zone extruder for melting

and extrusion, providing the ability to rapidly print

large structures with reinforced composites up to

150kg/hr. In addition, the printers offer an optional

5-axis machining head can provide smooth

surface finishes.

The printers have several other features,

including a nozzle rotation unit with a

temperature-controlled roller to flatten and

compress print bead, a vacuum pellet drying and

conveying system with high performance and

energy efficiency for continuous printing, axis print

speeds up to 20 m/min with axis rapid speeds up

to 60 m/min, changeable nozzles, and Siemens

SINUMERIK ONE controls, the leading platform

for advanced manufacturing.

Material Supply and Development

INNOMERIX PTY LTD, a CNC Design subsidiary business, has been established to supply a wide range of thermoplastic composites and currently supplies One Composites. Equipped with a sophisticated compounding line and advanced dosing systems for powder and fibre incorporation into the polymers. This allows material properties such as strength, pliability, impact resistance to be adapted for each application. Other properties such as UV protection, low flammability, and biocides to avoid marine growth can also be added as part of the manufacturing process.

The Result

One Composites CTO, Dave Biggar, says

Whilst investing in new advanced manufacturing technology may be perceived as a high risk, our experienced team quickly mastered the technology and identified a growing demand for large-scale 3D printed and/or machined components. The implementation of this technology has significantly increased our efficiency and versatility, enabling us to combine external project work with initial lightweight composite body production. As a result, our equipment is now being fully utilised, creating a need for additional production capacity and growth in our One Composites business.

Material Supply and Development

INNOMERIX PTY LTD, a CNC Design subsidiary business, has been established to supply a wide range of thermoplastic composites and currently supplies One Composites. Equipped with a sophisticated compounding line and advanced dosing systems for powder and fibre incorporation into the polymers. This allows material properties such as strength, pliability, impact resistance to be adapted for each application. Other properties such as UV protection, low flammability, and biocides to avoid marine growth can also be added as part of the manufacturing process.

The Result

One Composites CTO, Dave Biggar, says

Whilst investing in new advanced manufacturing technology may be perceived as a high risk, our experienced team quickly mastered the technology and identified a growing demand for large-scale 3D printed and/or machined components. The implementation of this technology has significantly increased our efficiency and versatility, enabling us to combine external project work with initial lightweight composite body production. As a result, our equipment is now being fully utilised, creating a need for additional production capacity and growth in our One Composites business.