Ueda MAAG SH250 Controls & Drives Upgrade

Ueda MAAG SH250 Controls & Drives Upgrade

Ueda Heavy Gear Works Ltd Project

Ueda Heavy Gear Works Ltd Project

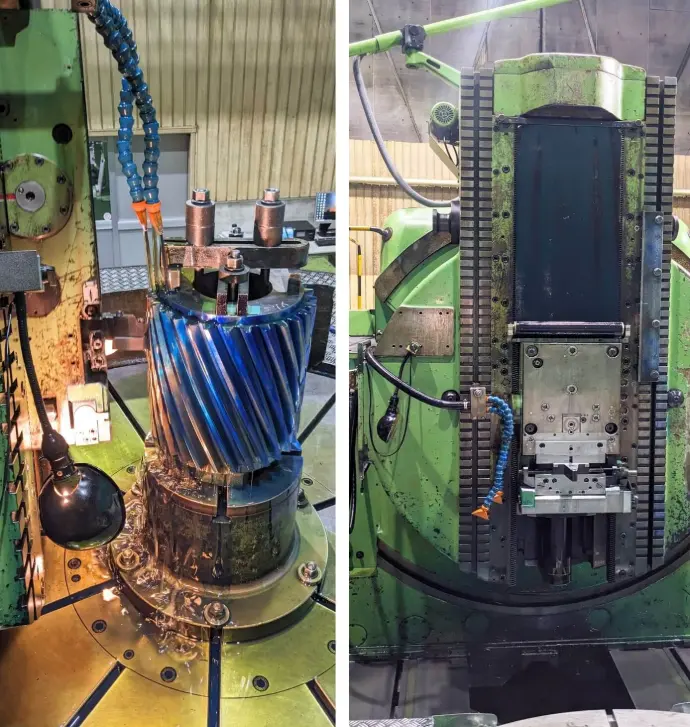

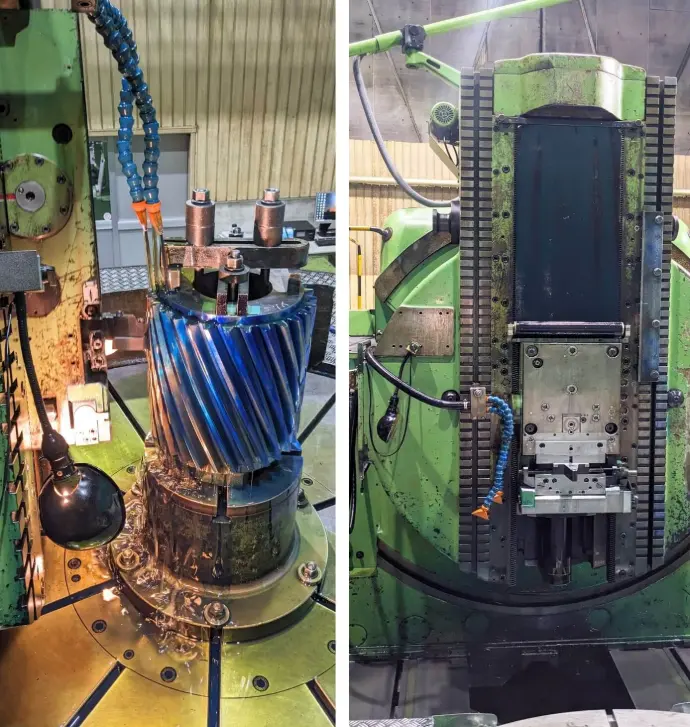

The Customer

Ueda Heavy Gear Works Ltd is one of Japan’s flagships of heavy industry companies. Established in 1893, Ueda Heavy Gear Works has become the leading gear manufacturer in Japan, supplying large gears, pinions and other power transmission components to all major steel and machinery manufacturers in Japan. Located in Osaka, specialising in manufacturing large cylindrical girth gears, pinions and bevel gears, Ueda Heavy Gear Works has a large number of MAAG gear shaping machines.

The Customer

Ueda Heavy Gear Works Ltd is one of Japan’s flagships of heavy industry companies. Established in 1893, Ueda Heavy Gear Works has become the leading gear manufacturer in Japan, supplying large gears, pinions and other power transmission components to all major steel and machinery manufacturers in Japan. Located in Osaka, specialising in manufacturing large cylindrical girth gears, pinions and bevel gears, Ueda Heavy Gear Works has a large number of MAAG gear shaping machines.

The Challenge

As of April 2024, Siemens officially ended the product lifecycle for some of the SINUMERIK 840D Powerline CNC systems and the SIMODRIVE 611D drive components that included power modules and control cards. With the discontinuation of manufacturing and the end of guaranteed factory tested spare parts availability, users of these systems are advised to upgrade to current platforms to ensure long-term maintainability and operational reliability.

The MAAG SH600/735 gear shaping machine currently utilizes the SINUMERIK 840Dsl CNC system. It was originally retrofitted by CNC Design in 2014. However, certain components within its operator panel are derived from the older SINUMERIK 840D Powerline family, which has now reached end-of-life. This partial legacy configuration poses a risk to service continuity and spare parts availability.

The Challenge

As of April 2024, Siemens officially ended the product lifecycle for some of the SINUMERIK 840D Powerline CNC systems and the SIMODRIVE 611D drive components that included power modules and control cards. With the discontinuation of manufacturing and the end of guaranteed factory tested spare parts availability, users of these systems are advised to upgrade to current platforms to ensure long-term maintainability and operational reliability.

The MAAG SH600/735 gear shaping machine currently utilizes the SINUMERIK 840Dsl CNC system. It was originally retrofitted by CNC Design in 2014. However, certain components within its operator panel are derived from the older SINUMERIK 840D Powerline family, which has now reached end-of-life. This partial legacy configuration poses a risk to service continuity and spare parts availability.

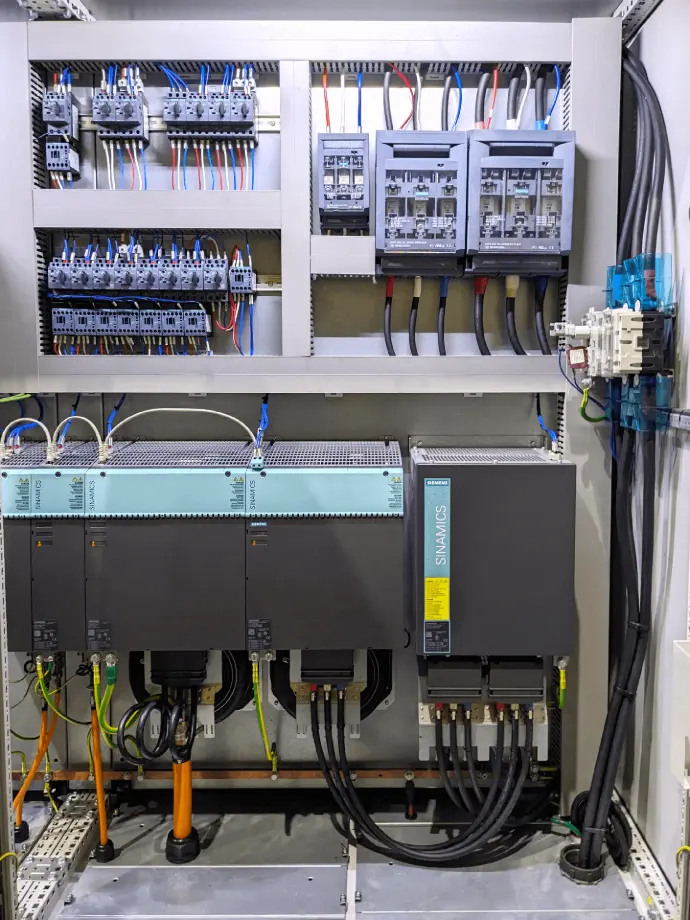

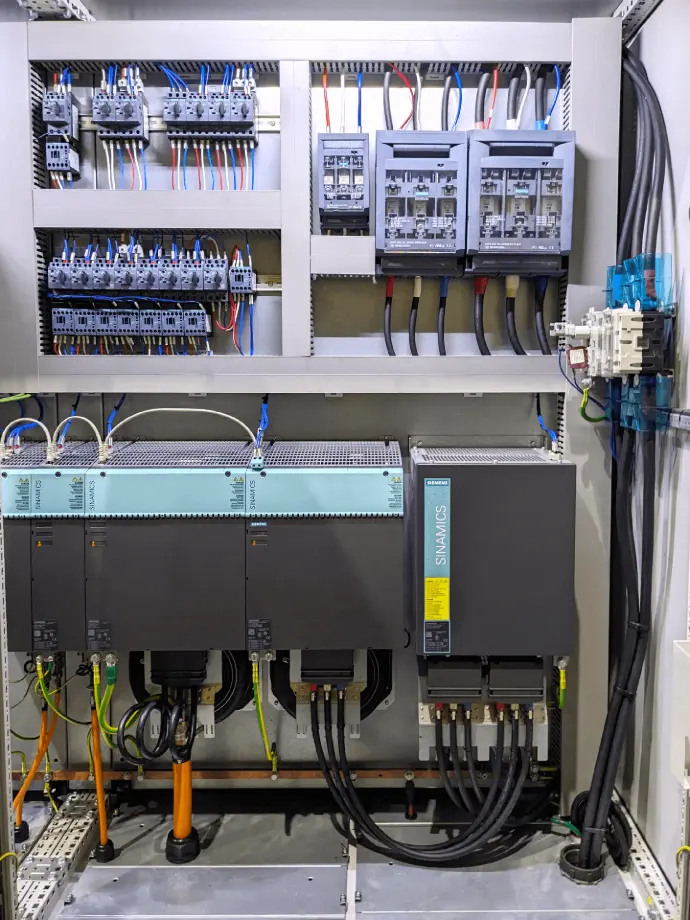

The Solution

To align the MAAG SH600/735 with current technological standards while minimizing disruption, a strategic retrofit was proposed. The upgrade involved replacing the CNC NCU and operator panel components with the latest generation:

The Solution

To align the MAAG SH600/735 with current technological standards while minimizing disruption, a strategic retrofit was proposed. The upgrade involved replacing the CNC NCU and operator panel components with the latest generation:

SINUMERIK ONE CNC

New Operator Panel, Machine Control Panel & Hand-Held Unit

On-site installation, commissioning & training plus updated documentation

SINUMERIK ONE CNC

New Operator Panel, Machine Control Panel & Hand-Held Unit

On-site installation, commissioning & training plus updated documentation

The Outcome & Benefits

By focusing the upgrade on control and interface components only, the retrofit reduces downtime, lowers investment cost, and will ensure compatibility with the MAAG 250/300E scheduled for its upgrade in the near future, thereby streamlining future maintenance, spare parts management, and machine operation.

Outcome & Benefits

- Future-Proofing: The SH600/735 hardware & software will be harmonised with the SH250/300E, once upgraded, simplifying lifecycle service and support.

- Operational Continuity: No need to replace motors, S120 drives, or measuring systems.

- Cost-Efficiency: Maximizes use of existing assets while leveraging modern CNC capabilities.

- Ease of Maintenance: Ensures long-term availability of spare parts and Siemens support.

This case exemplifies a targeted modernization approach, preserving core mechanical assets while enabling a digital-ready control architecture through SINUMERIK ONE.

By focusing the upgrade on control and interface components only, the retrofit reduces downtime, lowers investment cost, and will ensure compatibility with the MAAG 250/300E scheduled for its upgrade in the near future, thereby streamlining future maintenance, spare parts management, and machine operation.

Outcome & Benefits

- Future-Proofing: The SH600/735 hardware & software will be harmonised with the SH250/300E, once upgraded, simplifying lifecycle service and support.

- Operational Continuity: No need to replace motors, S120 drives, or measuring systems.

- Cost-Efficiency: Maximizes use of existing assets while leveraging modern CNC capabilities.

- Ease of Maintenance: Ensures long-term availability of spare parts and Siemens support.

This case exemplifies a targeted modernization approach, preserving core mechanical assets while enabling a digital-ready control architecture through SINUMERIK ONE.

Client Feedback

The CNC retrofit of the MAAG gear cutting machines can be realized by knowing the mechanism and features of the MAAG gear cutting machines and putting the latest Siemens technology on it.

CNC Design Pty Ltd is the only company in the world that can do this. MAAG gear cutting machines are still widely used in the production of large gears.

With the help of CNC Design Pty Ltd, I hope we will continue to use MAAG gear cutting machines with great care.

Client Feedback

The CNC retrofit of the MAAG gear cutting machines can be realized by knowing the mechanism and features of the MAAG gear cutting machines and putting the latest Siemens technology on it.

CNC Design Pty Ltd is the only company in the world that can do this. MAAG gear cutting machines are still widely used in the production of large gears.

With the help of CNC Design Pty Ltd, I hope we will continue to use MAAG gear cutting machines with great care.

DOWNLOAD Ueda MAAG SH250 Controls & Drives Upgrade Case study

DOWNLOAD Ueda MAAG SH250 Controls & Drives Upgrade Case study